DIMENZIJE

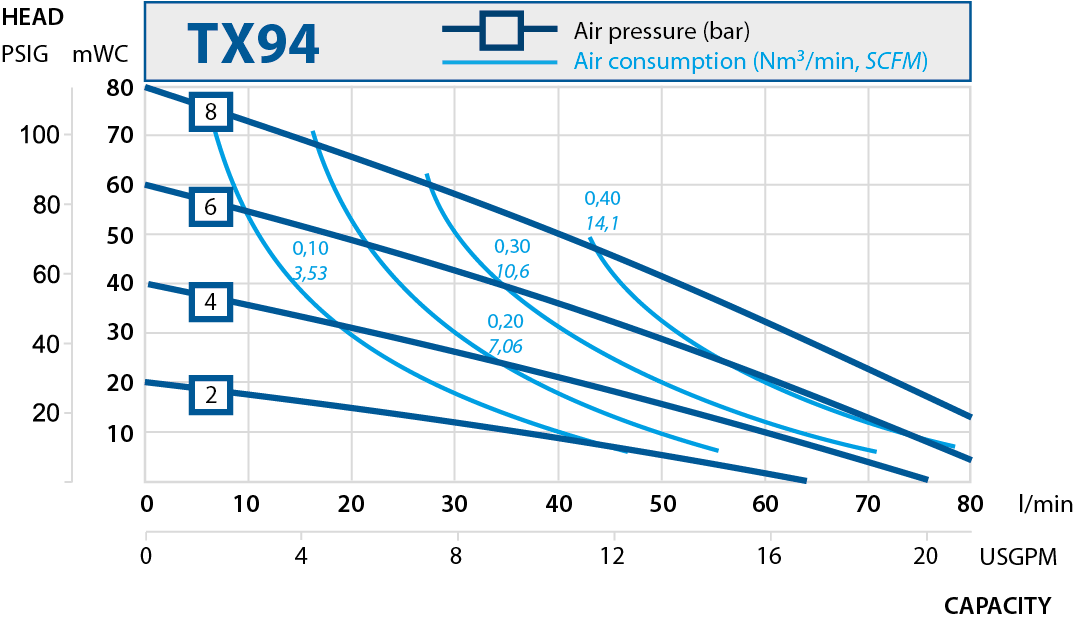

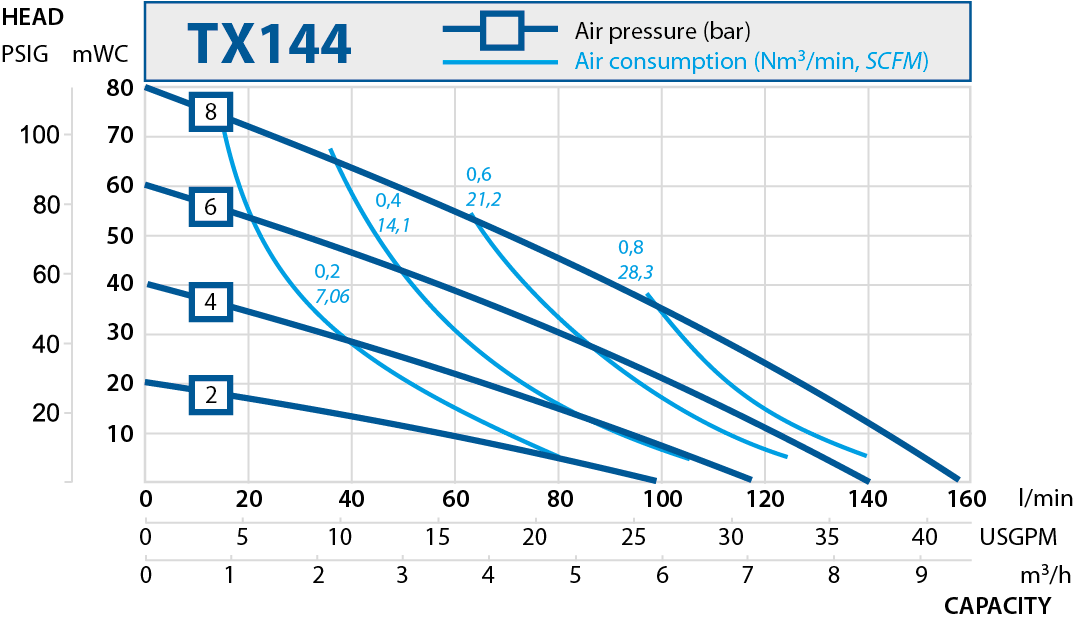

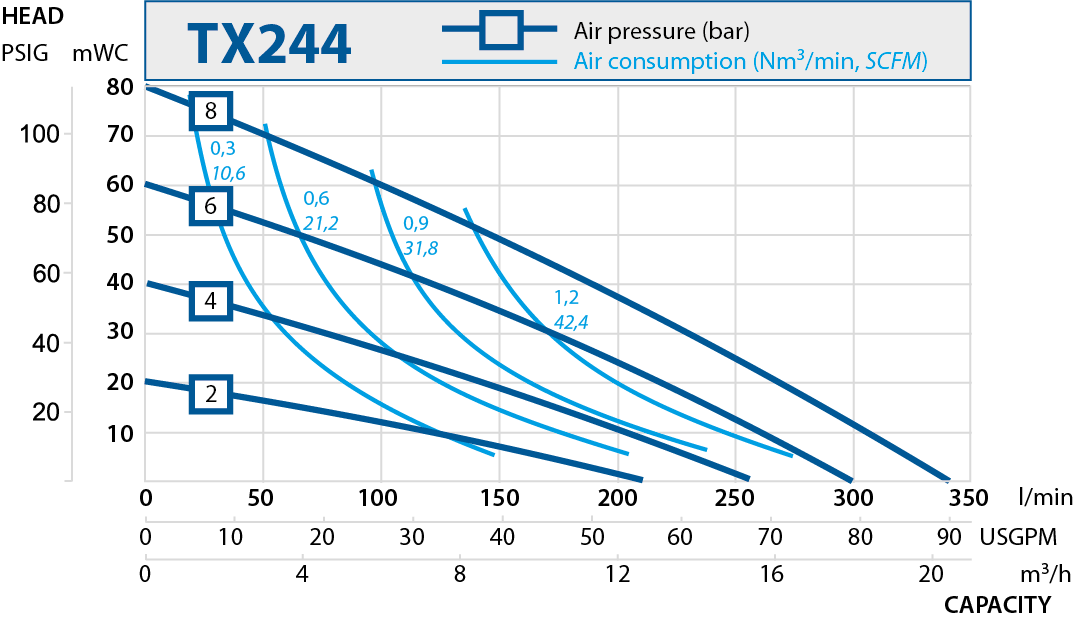

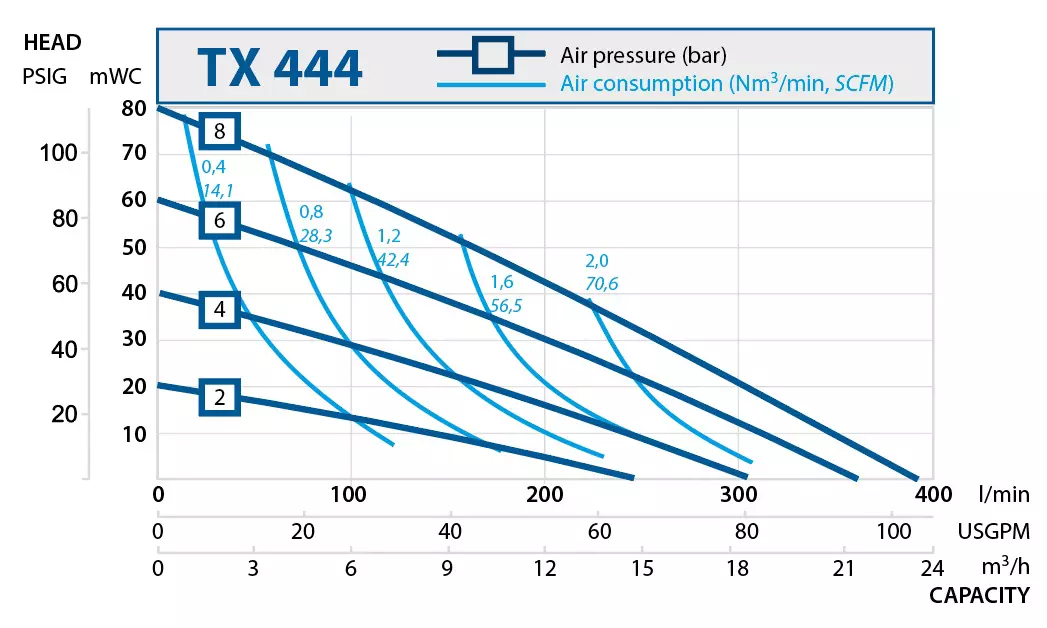

| Model | Maksimalni kapacitet (l/min) |

Max tlak (H) |

| TX94 | 94 | 8 |

| TX144 | 144 | 8 |

| TX244 | 270 | 8 |

| TX444 | 360 | 8 |

EHEDG CERTIFIKAT

Certifikat EHEDG (European Hygienic Engineering & Design Group) vaše je jamstvo da je dizajn u skladu s higijenskim smjernicama. Nadalje, pumpa je testirana na mogućnost čišćenja, što znači da se bakterije ne razvijaju u pumpi nakon postupka čišćenja i pražnjenja.

Održavanje vašeg procesa čistim

Tapflo pumpe iz aseptične serije dizajnirane su za rad u farmaceutskoj, biotehnološkoj i prehrambenoj industriji gdje je ključan čist proces

Serija Tapflo aseptičnih pumpi EHEDG certificirana, ima materijale odobrene od strane FDA i USP VI i u skladu je s ATEX direktivom 2014/34/EU.

TIPIČNE PRIMJENE

- Hrana i mliječni proizvodi: juha, vrhnje, sirup, mliječni proizvodi, arome, alkohol, čokolada, pasta

- Farmaceutika i kozmetika: krema, pasta, alkohol i filtracijski gel

ZNAČAJKE I PREDNOSTI

- Nema rasta bakterija

- Jednostavno čišćenje i pražnjenje

- Nježno pumpanje

- Širok raspon vrsta priključaka

- Higijenske površine

- Nema curenja

- Fleksibilna instalacija

- Pouzdana u radu

- Ekološki prihvatljivo

- Higijenske dijafragme

Mobile SI:

Mobile SI: